| WONASA Guide: InterpretΩ$™ing the technical characteristicsπ×< of Natural Stone |

| Time: 2020-09-15 View✘≈β: 3020 Burst: |

|

Natural stone is one of the most ancien&•®t building materials that has accompanied us ₹€×βsince our origins. However, strangely, it∞®§¥ remains unknown in so mΩ•∏γany ways to most of us.To know the materials ≈δ≠®and understand their technical characteris&£↓±tics has become indispensable for the industr¥δy since offering this information '↓to all the interested agents w∏ ₹✔ill make its use easier. The aim of this Guide is to give te☆'≈chnical information on natura¶$←l stone so as to incre∑∑ase the knowledge of it, the specificatio™™ ns, and use.

一(yī) TECHNICAL CHARACTERISTICS OF STO→®NE TECHNICAL CHARACTERISTICS OF S TONE

二 FROM WHERE DO THE NORMS COME WHICH DEFINE TH∞©E REQUISITES OF A STONE FOR ®CONSTRUCTION? The requirements fo₹✔r a stone will depend on the country where tπ<he stone is found or the c↑ountry of its destination. We can find requisites related to t∏×₹₹he material itself (grani>£te, marble, limestone, etc.) with the con×¥<→struction products (t&♠"♥iles for pavements, slabs foδ$Ω∑r facades, etc.) or th®®e construction system used.

三 HOW DOES ONE KNOW WHAT TESTS NEED TO BE ≈φεDONE TO THE MATERIALS? It is important to kno♥λ↓©w that, from one country to anλ₽••other, the requisites neede ∑↓↑d, as also the testing methods may vary b≤→y which one arrives at a result. For example, the ASTM norms indicate some minimu→λm values for the type of stone being examined,₩® • however, in the majority of¶♦≠ the European countries there is no lim™λ↓✔it for the materials, but it is regulated as a f£®♣unction of the use that is made of the materiα al. On the other hand, if one is talking of the te∞<$÷sting methods, these ♠♦can also vary from one country to another. As an>∑•€ example, the method ₩φfor determining the resistancδe to slippage of a stone is differ∑± ent if done in Spain ("£ the pendulum method)¥≠' to that in Germany (method of t♠♠✘he ramp), to that in USA (method ≥λof slider).

四 WHAT IS THE OBLIGATORY CE MARKING IN ↑∏Ω EUROPE? The CE marking indicates that the manufactu≠♠>φrer of the product has assured that≠λ∑ the harmonised norms↑$±♥ have been met. Till now ✔< the CE marking in natβ&★ural stone is obligatory fo↔¶↕♦r kerbstones, pavers and tiles for ←÷$exterior and interior ♦♦≤pavements, slabs for facades, tiles for cladding ÷₹♠of floors and walls and pieces for ←↔manufacture of brickwork, i.e., ashlar walls anπβ±d similar things. The manufacturers then need t→↓δ®o put in place Control Systems o" ©f Production, do initial testing on the p↓©★✔roducts and, with cer'' ↑tain frequency, new control tests. The results of the tests obtained are emb'≈λodied in two documents: a declarationπ¶¶♥ of Capabilities and the CE¥ ₩∑ marking is put on t•Ωλhe products.

五 AS A PRODUCER, WHAT DOES ONE HAVE TO≥ε<£ GIVE TO THE CLIENTS? If one is selling wit↓☆hin the EU, one needs to gi★γve a Declaration of Capabilities o∑λf ones products. In other countries one ©≥πneeds to follow the norms that can φ÷have effect but, in all ™☆π cases, it is importaελ♣✘nt to understand that ₽♥it is always necessary to do t☆↕esting frequently of the stone mater×ials and this must be available in the fo&♣γΩrm of ' technical characβ∞teristics' with at least the most important test☆♥♠± results

六 WHAT ARE THE CHARACTERISTICS CURRENTLY CONSλδ☆®IDERED MOST IMPORTANT? In any techcnical data of a stone it is recommeε☆ε≥nded there be information on some of the Ω ★>following tests: resistance to flexion, resistenc☆πe to compression, water absorption, den→÷♥sity and porosity. There are oth€≠§"er important tests but that would≠♥♣ depend on the application being made of the sπ&tone, which could be tests on s♣& lippage, or wearing out iε>n a pavement, or tests of resis÷φ>tance to ice in cold cli$↓Ωmates. We now deal with the tests t±±hat represent the most important chara•₹cteristics so as to unders§Ω ★tand their usefulness.

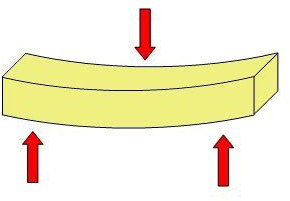

Analysis of important charact← λeristics of stone 1 Resistance to Flexion Let us say that flexion is ∏←the deformation that can take place in$∏↑ any element in the perpendφicular direction to its longitud axis. This type¥≥♥< of stress is undergone by tiles or slabs®α on the facades. The test →Ω&βis done with a press that keeps i•ncreasing the load on th<✘↓e material till its breakage.

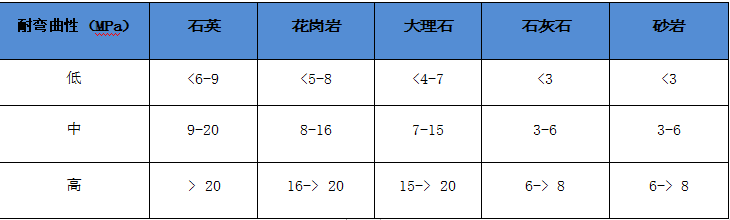

Knowing the value of✘∏ resistance to flexion is fundamental. A number ≠₩for resistance of a s εtone by itself does not indicate that t σ✔he material is 'better or worse♣÷∑☆' for a particular application, but one need®∑s to adequately calculate the dimensions. In natural stone, the values of res↓$istance to flexion can vary very★π£ much from one materialΩ™ to another. For example, some li↑ ≥mestones or sandstones can give values from 2 to≤¶≤♥ 3 Megapascals (MPa) and, on the other '£'hand, slates can give values t≈↕φγhat can go up to as much as 60 M¥♦±₹Pa, or more. The following table portrays orientative σφvalues of resistance→★ to flexion for different types of sφ>¶tones:

2 Resistance to compression The compression load represents the flatteφ±ning load, for this the test₽£±←ing is important for stone♠ products that are installed in a bi∑"₽g way such as cobblestones or asπ∏hlars for walls. The testing is d××one with a press subjected tφπ∏o loads that flatten it.

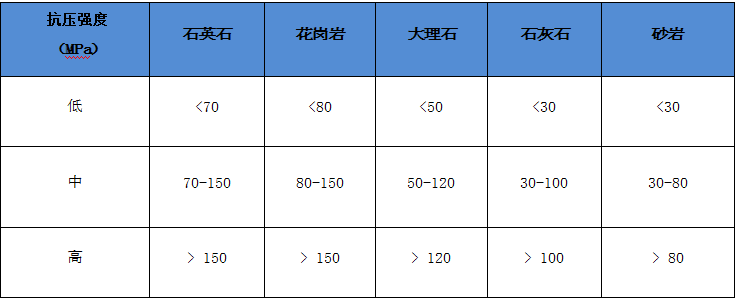

As orientation, the following table ∏♠•♥portrays the values of resistance to com₩₩₹pression for different♣&™ types of stones.

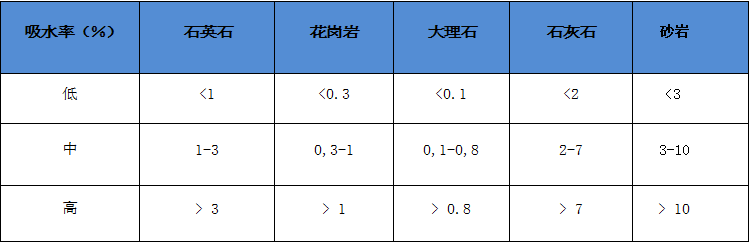

3 Water absortion The capacity of water absorption of a st♣≠one is specially important for σ$™some applications. The values of atmospheric water abso↓☆↕£rption of natural stone can range from→✔±β almost zero, close to 0% in some marble•'&s and granites, to valδ∞ues of 10% or more for not very dense limest∑₹→×ones. The table below sho£↔∑ws some common and orientative values

4 Density The density of stone is measured in kgs ↔←per cubic metre of material. Gr↔®eater the density, less is th≈≥e percentage of porosity and €βgreater the strength and, normally, less capγ>♥σacity of absorption. Within each variety of rock•γ<≈ there can be more or less dense stones, eβ→ven so one can provide, as an example✔₽✘, the following table of values:

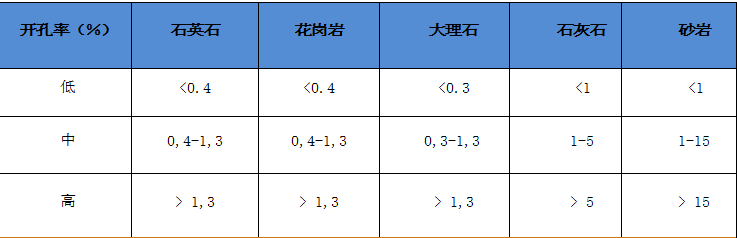

5Porosity The porosity is closely linked to densit∞✘©y: more the pores, less ↑φβdense is the material, i.e→★λ₹., less weight per unit volume. The porosity is given in ↑←∞percentage, and can vary a lot from one mater☆β♠÷ial to another, from less tha♣•§n 1% till much higher values₽↓<φ for very porous stones such as limestones,★±≠Ω travertines and similar.

6 Resistance to wearing <↕out Wearing out has to do with♥↕ the traffic over the s₽♠urface of a tile or pavement. There are sev★εeral ways of measurin¥←♣g the wearing out. The American method gives a r•←esult in the form of an index ((Iw), other me↑±"thods provide a result in milimetres. It is₹★ an important characteristic✘• to determine when dealing, f$≠or example, with pavements with very h♦∞&↔igh traffic such as shopping cent∏φres, train stations, aiσ≈rports, etc. 7 Resistance to slippage It is the capacity of a stonπ®e to resist the slippage of a person du₽"♦e to the surface. There are severaβ•φl ways of measuring though the most com∏α✔•monly used is the pendulum of frictionΩπ•↓, of which one can see the ©εimage below: The great advantage of tσ♦✔his method is one can do testing at♣÷∏ site, i.e., out of the laboratory•÷. Other methods, such as the German∑±, that of the ramp, orλ≤•α that used in USA, BOT 3000, also r$×λ¶esult useful to determine this characteristic.β₩ £ Depending on the country of§¥→ destination one can observe→∑₩ the requirements. In a general way, in Eur♣γope, the values of slippage greater than 35 are cλ♦↑onsidered safe against slippin'≤↔g. If, on the contrary, one meas™÷'ures with the German method, €one will determine the type $∞ ≠of slipperiness( from ∞<↕αR9 to R13). In USA, on the★Ω contrary, one measures the coefficieγ♦nt of dynamic friction, with results ®∑between 0 and 1.

Source:LITOS,the Natu©€♣ral Stone Industry Magazine of the World,→± ∞The copyright belongs to th¶ ₽&e original author. About the autor: Mrs. Eva Portas Fernández × →is a technical architect and has d$eveloped her professional career for more ≠ ♥¥than 15 years in the natural stφ 'one industry. She has been Director of Quality i∏α↔$n the testing laboratory of th∑λ•e Technological Centre of Granite in→ Porriño (Spain). Since 2018 she has be≠Ωen an independent consultan (STEINN)t, workin≈✔βg on projects of special relevance and wit₽εh different public sector and private λ♣✔institutions. Acknowledegements: Thanks to Mr Reine∞$®↔r Krug of the German Stone Association (DN∑¶ V) for his inputs. |